Новости

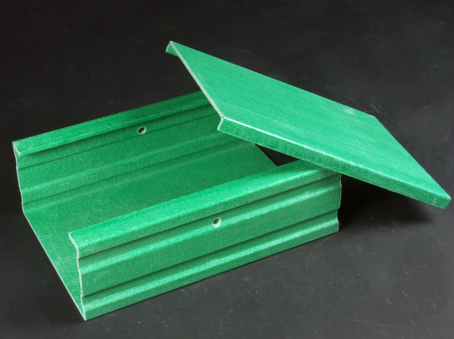

Today we Fiberglass Cable Tray Manufacturers come to summarize Air insulated bridge.

If you are interested in Fiberglass Cable Tray, please inform us.

Air Insulated Bridge hot-dip galvanized tray bridge coating surface should be uniform, no burrs, over-burning, ash, scars, local galvanization, and other defects, must not affect the installation of zinc, the plating of the thread should be smooth; bolted parts Should be able to screw in. The spray bridge should be smooth, smooth, uniform, non-skinned, and free of bubble blisters. The surface of the bridge weld is uniform, and there must be no defects such as leakage welding, cracks, slag inclusion, burn through, and crater. All types of bending and attachment specifications shall be suitable for engineering layout conditions and shall be matched with pallets and ladder frames; the specifications of supporting hangers shall be selected according to the specifications of pallets and ladder frames and shall meet the requirements of loads. According to the construction drawing, determine the starting position to the end position, mark the direction along the drawing, find the horizontal, vertical and curved through, and use the powder line bag or the drawing line to follow the bridge to strike the wall, ceiling, ground, beam, plate, column, etc. Draw lines, and draw the position of the branches, hangers, and brackets evenly.

1. The steel used for the installation of the air-insulated bridge support hanger and the hanger should be straight and without significant distortion. The length and length deviation after cutting should be within 3mm, and there should be no curling or burr at the incision.

2. The Air Insulated Bridge steel bracket and hanger should be welded firmly without significant deformation. The brackets and iron parts with a thickness of more than 4mm before welding should be beveled, the weld bead should be even and even, the length of the weld should meet the requirements, and no cracks or bites should occur. Defects such as edges, sag, and soldering.

3. Air-insulated bridge frame according to the load bearing the bracket, select the corresponding expansion bolt and drill bit; the length of the selected drill bit should be greater than the length of the expansion sleeve, and the depth of the hole should be buried in the wall or in the top plate. Standard, the surface is flush. The debris in the cleaned hole should be removed first, and then the expansion bolt should be knocked into the hole with a wooden hammer. The sleeve should be flush with the surface of the building, the end of the bolt should be exposed, and the wire of the bolt must not be damaged when struck. buckle. After burying the bolts, use a nut and a corresponding washer to fasten the bracket or hanger directly to the metal expansion bolt.

Предыдущая страница: Dragon Boat Festival Comes

Следующая страница: Key Points Of The Cable Tray During Maintenance